News

The Potential of 3D Printing in Boat Manufacturing

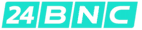

Companies in the Netherlands are investing in the use of 3D printing technology to manufacture hulls, with the expectation that it will lead to more affordable boat production.

A rigorous test was conducted, with Maarten Logtenberg using a sledgehammer to strike a sample of the new material. The results were impressive, as the hammer bounced off with minimal impact, leaving only a slight mark.

Following a two-year period of experimentation, a breakthrough was achieved in developing a unique blend of thermoplastics and fibreglass. This innovative material boasts exceptional strength, requires no additional coating for UV protection, and exhibits resistance to fouling and marine growth.

According to Mr Logtenberg, this material provides an ideal foundation for 3D printing a boat, offering a range of benefits that make it an attractive option for marine applications.

The marine environment is notoriously harsh, and boats must be designed to withstand its unforgiving conditions. This is one reason why traditional boatbuilding is often a labor-intensive and time-consuming process.

However, after months of fine-tuning the material's chemistry, CEAD was able to produce its first hull in just four days at its new factory. This marked a significant milestone in the company's efforts to revolutionize boatbuilding.

Mr Logtenberg notes that CEAD is automating nearly 90% of the boat-building process, significantly reducing production time. This streamlined approach enables the company to produce boats at a much faster rate than traditional methods.

Typically, building a hull takes several weeks. In contrast, CEAD can now print one every week, demonstrating the potential of 3D printing to transform the boatbuilding industry.

The story of CEAD's innovative approach to boatbuilding is one that 3D printing has long promised to deliver: a rapid, labor-saving production process that substantially reduces costs.

Although 3D printing has not always lived up to its promises, Mr Logtenberg is convinced that the maritime sector is an area where this technology can have a profound impact.

As co-founder of CEAD, a company specializing in the design and construction of large-format 3D printers, Mr Logtenberg has been at the forefront of this innovation. CEAD is based in the Dutch town of Delft.

Until now, CEAD's primary focus has been on providing 3D printers for other companies to use. However, with the advent of boatbuilding, the company has decided to expand its role and become involved in production as well.

Mr Logtenberg acknowledges that 3D printed boats still need to gain acceptance in the market. To address this, CEAD has taken a proactive approach, deciding to produce boats itself rather than simply providing the necessary equipment.

According to Mr Logtenberg, investors are often hesitant to commit to new technologies without a clear indication of market demand. By taking a hands-on approach to production, CEAD aims to demonstrate the viability of 3D printed boats and drive market growth.

Traditional fibreglass boatbuilding requires a mold and significant manual labor to ensure the vessel meets the required strength standards. In contrast, additive manufacturing streamlines this process by completing the necessary work at the design stage.

The design stage involves creating the software and printer, which can be a labor-intensive process. However, once this initial work is completed, the production phase can proceed with minimal human intervention.

3D printers operate by building up thin layers of material, following a predetermined digital design. This process enables the creation of complex objects with high precision.

As each layer is added, it bonds to the previous one, allowing for the formation of a single, seamless object. This approach enables the production of objects with intricate geometries and structures.

During the production phase, the primary requirement is a steady supply of the base material. With this in place, human intervention is minimal, and the production process can proceed autonomously.

One of the key benefits of additive manufacturing is the ability to make design adjustments without significant changes to the build process. This flexibility enables companies to respond quickly to changing market demands or customer requirements.

While 3D printing has made significant inroads in various industries, including dentistry, its application in boatbuilding poses unique challenges. Creating a vessel capable of withstanding real-world marine conditions requires a distinct approach.

CEAD's largest 3D printer, measuring nearly 40m in length, has been used to print an electric ferry for a customer in Abu Dhabi. This project demonstrates the company's ability to produce large, complex vessels using additive manufacturing.

Since establishing its Marine Application Centre in Delft, CEAD has made significant progress in boatbuilding. In the past 12 months, the company has produced a prototype 12m fast boat for the Dutch Navy, similar to a RIB.

Mr Logtenberg notes that traditionally, the Dutch Navy would have to wait years for a new boat, incurring significant costs. In contrast, CEAD was able to deliver the prototype in just six weeks, at a fraction of the cost.

Furthermore, CEAD can learn from the prototype and produce another vessel in the same timeframe, with the added benefit of being able to recycle the original boat. This approach enables rapid iteration and improvement.

Another area where 3D printing is gaining traction is in the production of unmanned vessels, such as nautical drones. CEAD recently participated in a test with Nato Special Forces, where drones were built on-site in a matter of hours, with designs adapting to operational requirements.

According to Mr Logtenberg, the flexibility of 3D printing is a major advantage. By relocating production closer to the end-user, companies can respond quickly to changing demands and reduce logistics costs.

Even large 3D printers can be transported in shipping containers, allowing for deployment in remote or hard-to-reach locations. This mobility enables companies to produce boats and other vessels in a variety of settings.

The size of the vessel is not a limiting factor, as the 3D printing process can accommodate a wide range of designs. As long as the base material is available, the machine can produce boats of varying sizes, from small work boats to larger military vessels.

The only logistical consideration is the transportation of the base material, which is highly efficient due to its compact packaging. In contrast, traditional boatbuilding often requires the transportation of large, finished vessels.

In the port city of Rotterdam, a company called Raw Idea, with its 'Tanaruz' brand, is exploring the potential of 3D printing in the leisure market, particularly in boat rentals.

Joyce Pont, Raw Idea's managing director, notes that while consumers may be hesitant to adopt 3D printed boats due to their novelty, the rental market is showing significant interest. The unique aspect of 3D printed boats can be a major marketing draw.

The use of social media platforms can help generate buzz around 3D printed boats, with customers eager to experience and share their encounters with these innovative vessels.

Raw Idea is also highlighting the eco-friendly aspect of its 3D printed boats, which are made from a combination of glass fiber and recycled consumer plastics, such as fizzy drink bottles.

Although the current cost of 3D printed boats is comparable to traditional vessels, the use of recycled materials increases production costs. However, as the technology scales up and becomes more efficient, costs are expected to decrease significantly.

Ms Pont is confident that within five years, 3D printed boats will dominate the market for fast-driving boats, such as work boats and speed boats, due to their improved performance and reduced production costs.

The marine industry is heavily regulated, and certification authorities are working to keep pace with the rapid innovation in 3D printing. Both Raw Idea and CEAD are engaging with European regulators to ensure compliance with existing standards.

As the industry continues to evolve, regulators must adapt to the unique characteristics of 3D printed boats, which often cannot be directly compared to traditional vessels.

The development of new materials and production methods is driving innovation in the marine sector, with companies like Raw Idea and CEAD at the forefront of this change.

While 3D printing has often been touted as a revolutionary technology, its impact has been uneven across different industries. Mr Logtenberg attributes this to the diverse range of applications and contexts in which 3D printing is used.

The varied nature of 3D printing applications can make it challenging to assess the technology's overall impact, as different industries and use cases may experience distinct benefits and challenges.

The field of additive manufacturing encompasses various applications, including metal printing, polymer printing, and large-scale printing, each with its own unique uses.

While some additive manufacturing applications have failed to gain traction due to competitiveness issues, others have successfully implemented the technology and are currently utilizing it.

Additive manufacturing is gaining traction in the shipping industry, albeit in specialized areas, rather than being used to construct entire ship hulls.

The potential of 3D printing in the maritime sector is still being explored, but the idea of printing entire ships in one process remains a distant goal.

Joyce Pont expresses doubts about the feasibility of automated shipbuilding in the near future, viewing the construction of luxury vessels like superyachts as a craft that will likely resist automation.

In contrast, Mr Logtenberg holds a more positive outlook on the future of additive manufacturing in shipbuilding.

Mr Logtenberg notes that he did not anticipate being able to build a 12-meter boat just a year ago, highlighting the rapid progress being made in the field.

Traditional shipbuilding involves a modular approach, and it may take around a decade or two for additive manufacturing to reach the point where entire ship hulls can be printed, pending further research into suitable materials.

As thermal plastics continue to be developed and improved, and machinery is scaled up, the possibilities for additive manufacturing in shipbuilding are expanding, raising the question of what can be achieved in the future.

News

Aberdeen to unveil new manager soon with Docherty set to take assistant role

Aberdeen has bolstered its interim management team with the return of Tony Docherty, who previously served as an assistant manager, to support Peter Leven, amid anticipation of a permanent appointment announcement that sporting director Lutz Pfannenstiel had indicated would be made “imminently”.

Ross County parted ways with Tony Docherty in December, and he has now taken on a new role.

Aberdeen have brought in former assistant manager Tony Docherty to support Peter Leven's interim management team, despite sporting director Lutz Pfannenstiel indicating that a permanent appointment was imminent.

Docherty's return to Aberdeen comes just a week after Eirik Horneland, a former coach of Rosenborg, Brann, and Saint-Etienne, emerged as a top contender to succeed Jimmy Thelin, who was sacked earlier.

As Aberdeen delays making a full-time appointment, speculation surrounding Eirik Horneland's availability has arisen, with reports suggesting the 50-year-old Norwegian may not be able to take on the role until summer.

Since Jimmy Thelin's dismissal on January 4, Lutz Pfannenstiel has been leading the search for a replacement, and he confirmed that Tony Docherty would be joining the team to assist Peter Leven during the interim period.

Dundee Utd are facing a challenging schedule, with four matches in 14 days set to take place on a weather-affected pitch.

According to Stavrum, Eirik Horneland's coaching style, characterized by intensity, would be a good fit for Aberdeen.

Tony Docherty initially joined Aberdeen in 2013 as part of Derek McInnes' management team and spent eight years at the club.

Before his stint at Aberdeen, Docherty served as McInnes' assistant at Kilmarnock and later managed Dundee and Ross County, but his time at Ross County ended in December when he was let go with the team at the bottom of the Championship.

Lutz Pfannenstiel praised Tony Docherty's experience, stating that he has a deep understanding of the club and will be a valuable asset during the transition period.

Pfannenstiel highlighted Docherty's extensive knowledge of the Scottish Premiership, gained through his experience as both a coach and manager, which will be beneficial to the team in the short term.

The club's managerial search is nearing its conclusion, and an announcement regarding the new head coach is expected soon, according to Pfannenstiel.

Peter Leven, who is serving as caretaker manager for the third time, expressed his enthusiasm for Tony Docherty's appointment.

Leven welcomed Docherty's return, stating that his experience will be a significant boost to the team, particularly during the upcoming matches.

Leven noted that Docherty was eager to join the team and that his presence will provide valuable support during both training sessions and matches.

Eirik Horneland left his position at Saint-Etienne in early February, at which point his team was fourth in France's second tier.

If Aberdeen decides to wait until summer for Horneland to take over, it will be similar to the six-month delay that occurred when Jimmy Thelin joined the club from Elfsborg in the summer of 2024.

For the latest news, analysis, and fan perspectives on Aberdeen, visit our dedicated page.

News

Peter Murrell faces allegations of misusing £459,000 in funds over 12 years

Allegations have been made that he bought various items, such as luxury goods, jewellery, cosmetics, two cars and a motorhome, in an improper manner.

Peter Murrell, the former chief executive of the Scottish National Party, is facing allegations of embezzling £459,000 from the party over a 12-year period.

An indictment document obtained by BBC News outlines the case against Murrell, who is the estranged husband of former Scottish First Minister Nicola Sturgeon.

The alleged embezzlement is said to have occurred between August 2010 and January 2023, according to the indictment.

It is claimed that Murrell used party funds to purchase luxury items, including jewellery, cosmetics, and vehicles, such as two cars and a motorhome.

The Scottish Sun was the first to report on the details of the indictment.

A preliminary hearing in the case is scheduled to take place at the High Court in Glasgow on Friday, 20 February, where Murrell is expected to appear.

During his initial court appearance at Edinburgh Sheriff Court, Murrell made no plea and was subsequently granted bail.

Murrell's arrest in 2023 was part of Operation Branchform, a police investigation into the SNP's funding and finances, which led to him being charged with embezzlement in April 2024.

Although Sturgeon was questioned by police as part of the investigation, she is no longer considered a suspect.

BBC News has obtained a copy of the indictment against Murrell ahead of his upcoming court appearance.

It is worth noting that the indictment is subject to change until the case is heard in court and may be amended throughout the judicial process.

The indictment alleges that Murrell purchased a £124,550 motorhome for personal use and created false documents to justify the expense as a legitimate party expenditure.

Murrell is also accused of using £57,500 of party funds to buy a Jaguar I-PACE car in 2019, and falsifying an invoice to conceal the true nature of the purchase.

Furthermore, it is alleged that when the Jaguar was sold in 2021, Murrell deposited more than £47,000 into his personal bank account.

The indictment also claims that Murrell embezzled £16,489 from the SNP to partially fund the purchase of a Volkswagen Golf in 2016.

A list of over 80 retailers is included in the indictment, where Murrell allegedly made purchases totalling more than £159,000 between 2014 and 2022, using party credit or charge cards for personal expenses.

The retailers named in the indictment include Harrods, the Royal Mint, John Lewis, Homebase, and Argos, among others.

It is alleged that Murrell used SNP credit or charge cards to make these purchases and then inserted false or inaccurate accounting codes and descriptions into the party's accounting systems.

The indictment also accuses Murrell of making purchases worth over £81,600 through Amazon using the same method.

Murrell served as the SNP's chief executive for 22 years before his departure.

Murrell and Sturgeon were married in 2010, but announced their separation in January 2025, after being together for many years.

News

Bangladesh Nationalist Party Wins Landslide in Country’s First Poll Since Youth-Led Protests

The public is looking forward to a shift back to democratic governance, following a 15-year period of authoritarian leadership by Sheikh Hasina.

In a significant shift in the country's political landscape, the Bangladesh Nationalist Party (BNP) has achieved a decisive majority in parliament, 18 months after widespread protests led to the ousting of Sheikh Hasina, the country's longest-serving prime minister.

The BNP secured over two-thirds of the seats in the recent general election, with the Jamaat party, the main Islamist party in the country, coming in second; meanwhile, the Awami League, led by Hasina, was not allowed to participate in the election.

As the BNP's leader, Tarique Rahman is poised to become the next prime minister, facing significant challenges in revitalizing the economy and restoring democratic principles after 15 years of authoritarian rule under Hasina's leadership.

In a concurrent referendum, voters also expressed support for comprehensive democratic reforms, which are expected to shape the country's future.

Following Friday prayers in Dhaka, Tarique Rahman expressed gratitude to his supporters, stating, "I am grateful for the love you have shown me"; his party has chosen not to hold a victory procession.

Rahman, who was elected to parliament for the first time, was among the 212 successful BNP candidates; according to the Election Commission, voter turnout was 59.44%.

This marks a significant turnaround for Rahman, who spent 17 years in self-imposed exile in London before taking over as party leader after his mother, former Prime Minister Khaleda Zia, passed away in December.

During his campaign, Rahman pledged to restore democratic principles and practices in the country.

The new government will need to address pressing issues, including economic revitalization, controlling rising food prices, and creating employment opportunities for the country's large youth population.

Rebuilding relations with neighboring India is also a key priority for the incoming government.

In the aftermath of his victory, Rahman received a congratulatory call from Indian Prime Minister Narendra Modi, who acknowledged his "remarkable victory".

Modi took to social media to reaffirm India's commitment to promoting peace, progress, and prosperity in both countries, citing their deep historical and cultural ties.

Although the BNP has pledged to bring about change, the party has faced criticism in the past for corruption and alleged human rights abuses during its previous tenure in government in the early 2000s.

The recent election represents a pivotal moment for the country, with one of the two main parties achieving a significant victory, presenting both opportunities and risks.

Proposed constitutional reforms include introducing term limits for the prime minister, establishing a directly elected upper house of parliament, strengthening presidential powers, and increasing judicial independence.

The reforms also aim to increase female representation in parliament, an area where significant progress is still needed, as evidenced by the limited number of successful female candidates in the recent election.

As the newly elected leader, Tarique Rahman will face intense scrutiny as he works to deliver on his promises to a predominantly young electorate eager for change, many of whom participated in the student-led protests that ultimately led to Hasina's removal and paved the way for the February 12 election.

-

News10 hours ago

News10 hours agoAustralian Politics Faces Questions Over Gender Equality Amid Sussan Ley’s Appointment

-

News7 hours ago

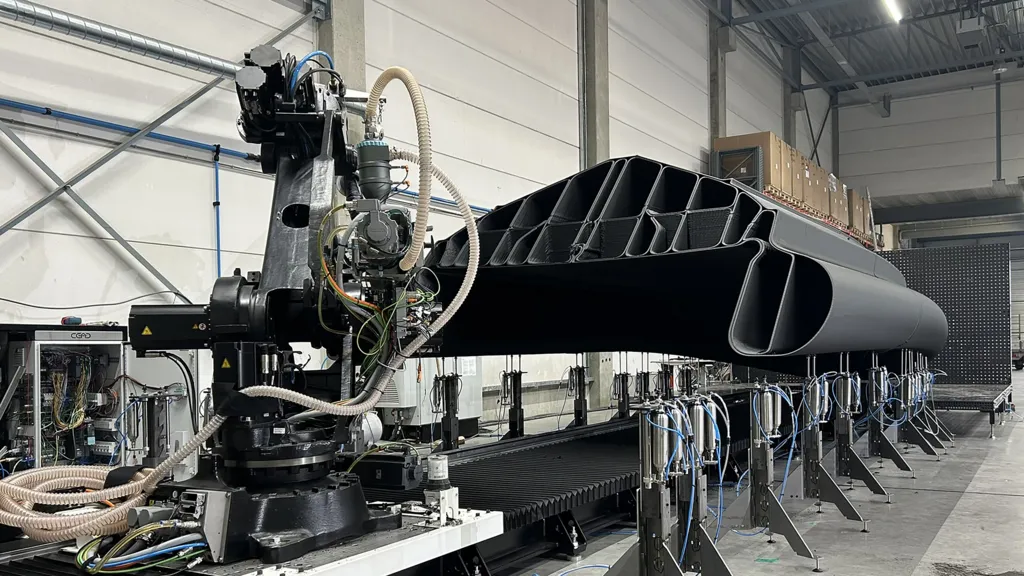

News7 hours agoFarage Says Reform to Replace Traditional Tory Party

-

News7 hours ago

News7 hours agoWrexham Pair Seek Win Against Former Team Ipswich

-

News12 hours ago

News12 hours agoLiberal Party Removes Australia’s First Female Leader

-

News10 hours ago

News10 hours agoUK Braces for Cold Snap with Snow and Ice Alerts Expected

-

News7 hours ago

News7 hours agoHusband’s alleged £600k theft for sex and antiques blamed on drug side effects

-

News2 days ago

News2 days agoSunbed ads spreading harmful misinformation to young people

-

Business12 hours ago

Business12 hours agoBBC Reporter Exposed to Cyber Attack Due to Vulnerabilities in AI Coding Tool